L&L BondPractical alternatives to traditional joining techniques

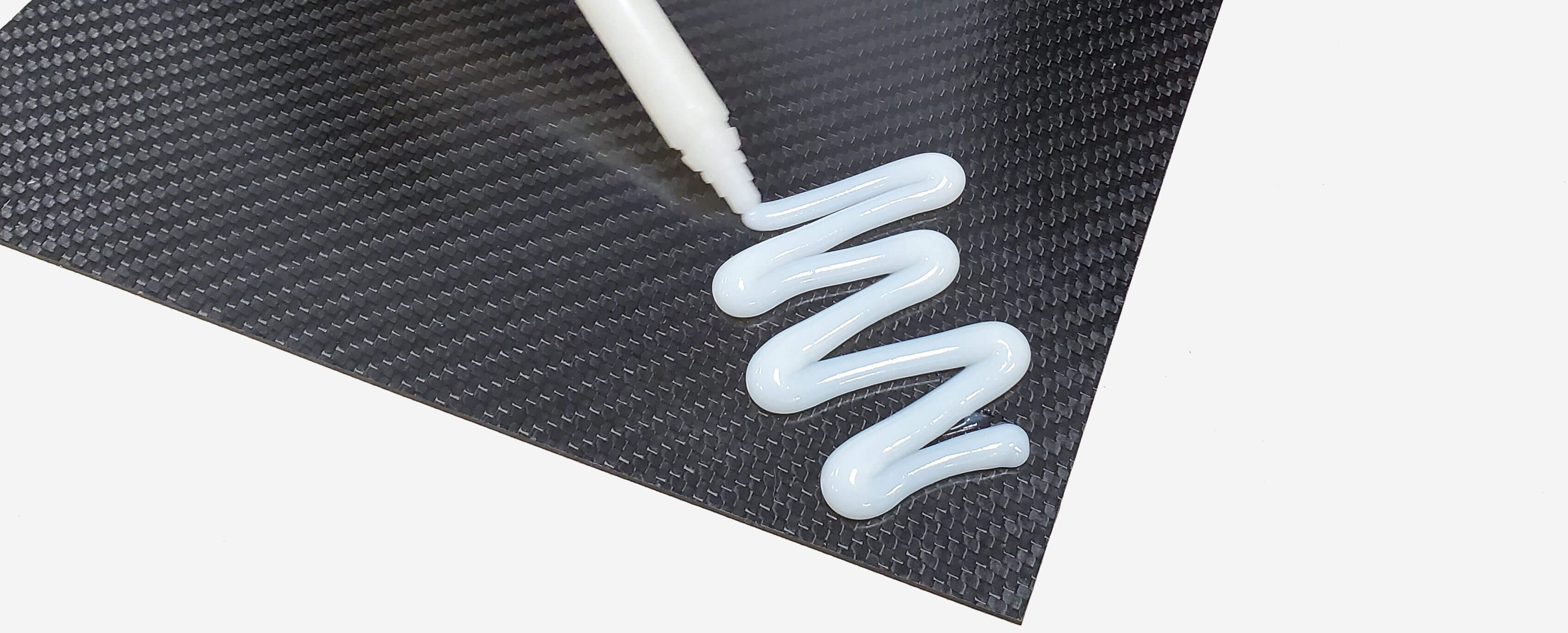

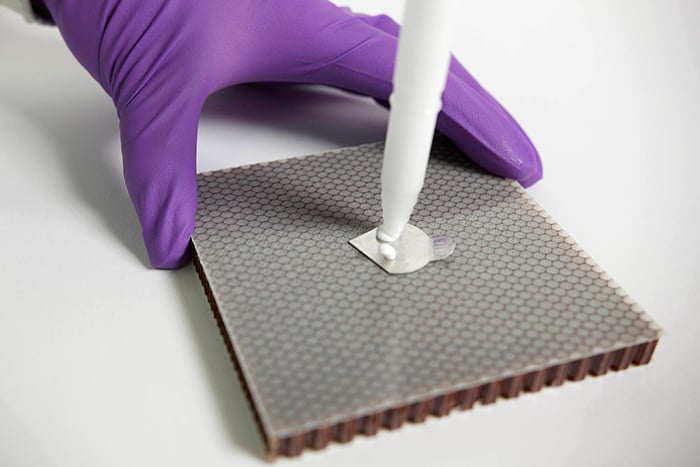

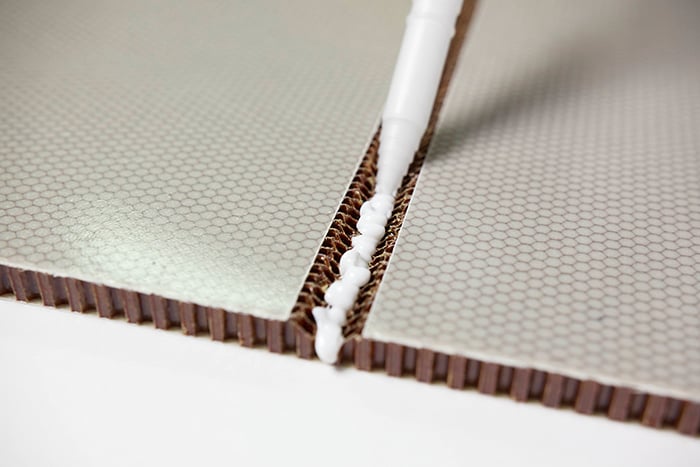

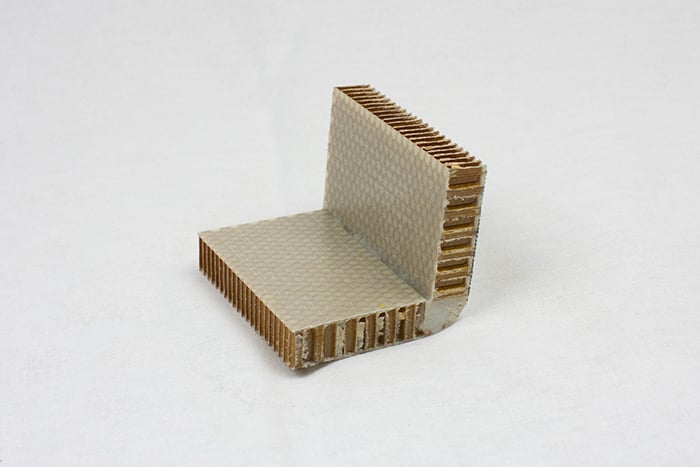

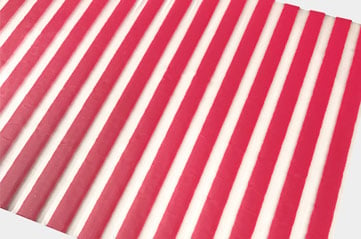

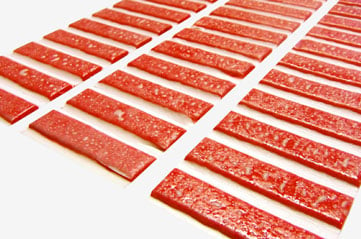

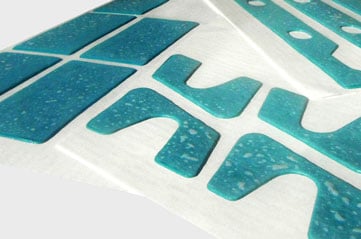

For more than 20 years, L&L has been supplying heat-activated adhesive tapes to replace and augment welding, brazing, and mechanical joining methods in automobile manufacturing. Ever since, we have used our expertise in adhesion technology to expand our range of solutions to other industries as well. We meet current market needs by offering structural adhesives with advanced properties in a variety of forms.

Let’s get in touch!

Are you interested in our Bond Solutions? We look forward to a conversation!

ContactBond

Solutions

Lightweighting initiatives often require the use of multi-material bonding across all industries. Our adhesive technologies are designed to create structural bonds and improve overall performance while at the same time help to prevent galvanic corrosion, improve durability, and improve worker safety and efficiency.