汽车领域

轻量化

轻量化

结构增强

结构增强

工艺优化

工艺优化

提升碰撞性能

提升碰撞性能

NVH优化

NVH优化

打造更轻、更强、更静音的汽车

在 L&L Products,我们助力汽车制造商设计出符合最高碰撞、舒适性和性能标准的车辆。我们的先进材料专为轻量化制造、抗碰撞、隔音和多基材粘接而研发,每项技术都能无缝融入现代生产线。

无论是密封腔体、强化车身结构,还是优化 NVH 性能,我们的热激活和常温固化系统都能满足当今乘用车、电动汽车和商用车的需求。

L&L Products 是您的创新合作伙伴

点击细分板块,了解详情

声学

粘接

增强

密封

Select a panel to see more information.

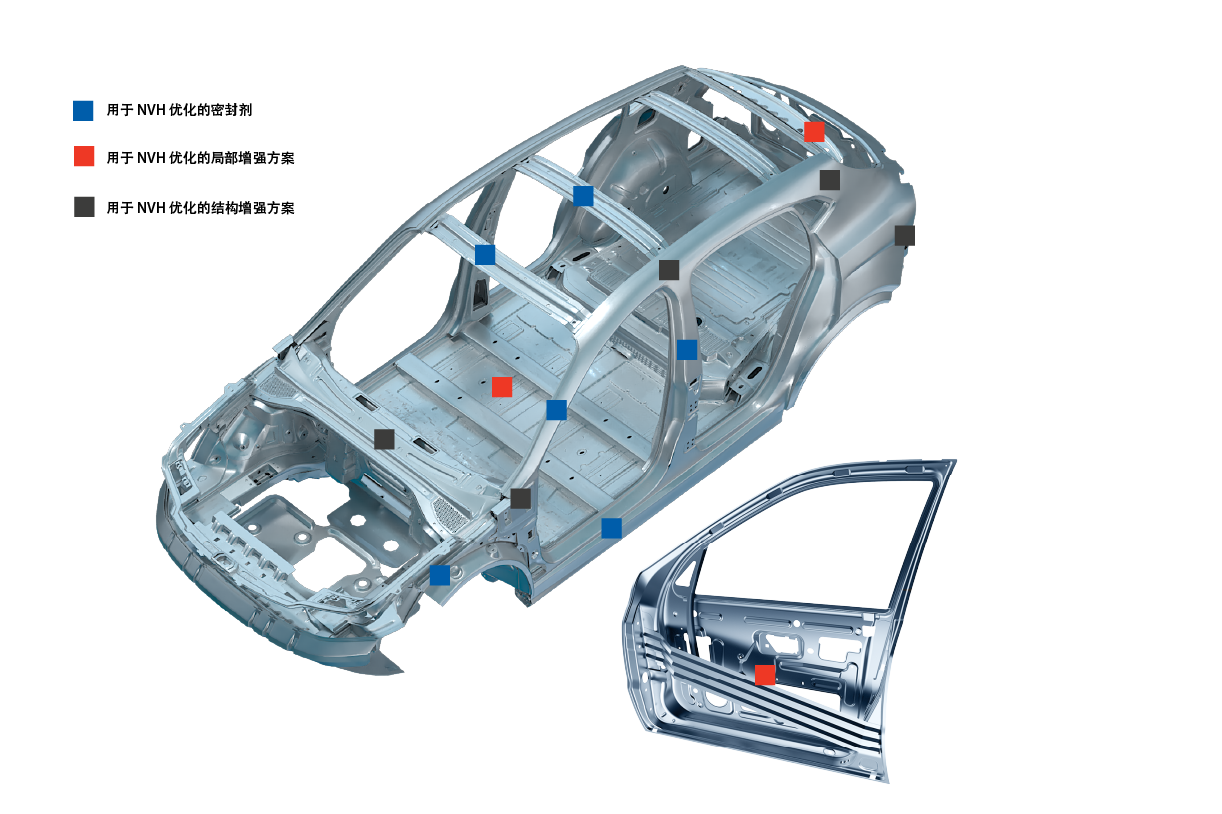

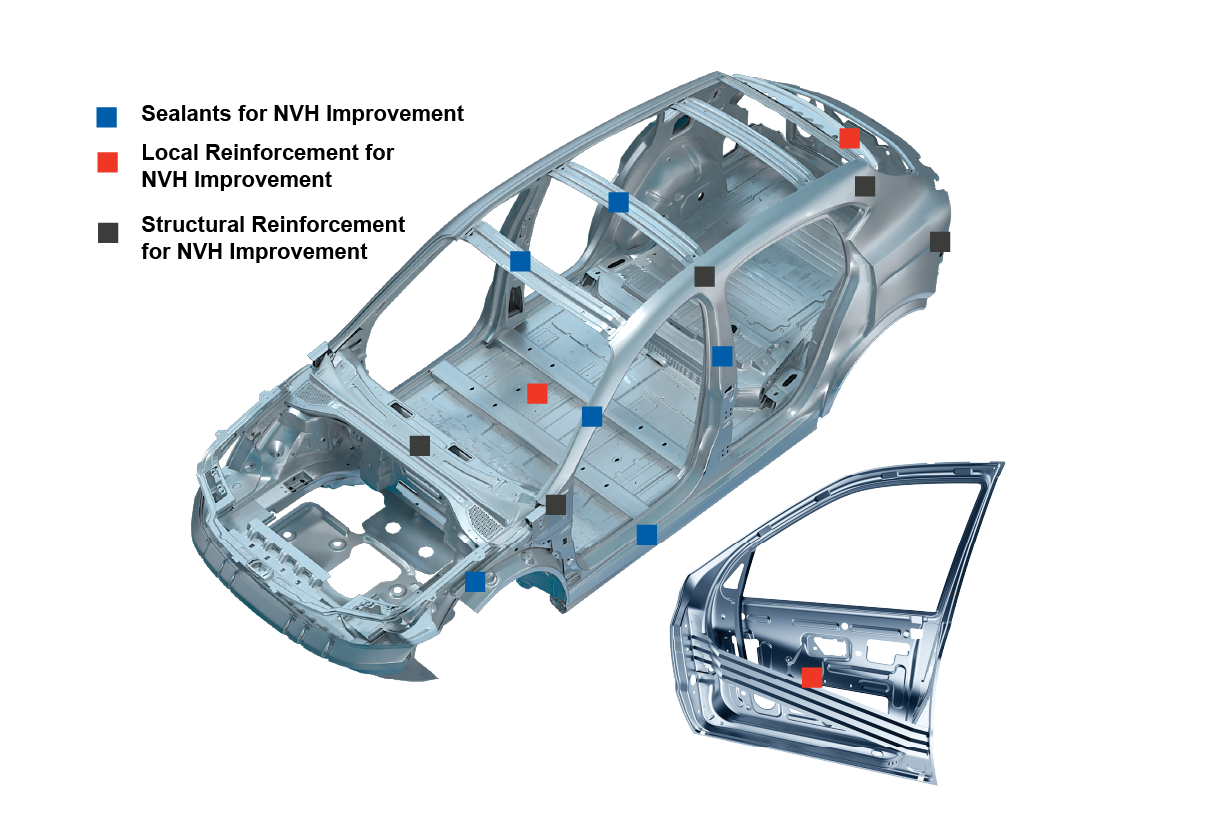

用于 NVH 优化的密封剂

专为密封和填充车架腔体设计的工程解决方案,助力提升 NVH 性能,同时防止水、灰尘和烟雾侵入。

核心特点

- 触感干燥,便于操作

- 无缝融入制造流程

- 具备抗颤振性能,提升声学效果

- 多种形式可选

相关解决方案

用于 NVH 优化的局部增强方案

复合面板加强件可提高面板刚度,减少长期使用后的疲劳损耗,并在大面积或无支撑区域提升 NVH 性能。该应用的典型方案是结构胶复合玻纤布。

核心特点

- 面板减振

- 长期抗疲劳性

- 支持使用更薄规格的面板

- 在未固化状态下具有优异的粘接性

相关解决方案

用于 NVH 优化的结构增强方案

CBS™ 技术集成于车架关键区域,以增加刚度并提升 NVH 性能。该解决方案结合了工程结构泡沫与定制设计的热塑性载体。

核心特点

- 提升结构刚度

- 热激活材料在电泳涂装前安装

相关解决方案

热激活粘接解决方案

在电泳涂装前应用,这些结构胶条在烘烤过程中激活,必要时可发泡以填补缝隙。

核心特点

- 高延展性和强度

- 压敏性,便于烘烤前定位

- 提升结构刚度和耐用性

- 提供可填补缝隙的发泡型产品

相关解决方案

复合结构增强技术

CBS™ 增强件提供截面稳定性和多向载荷路径管理,以吸收能量、提升抗冲击性能和抗碰撞性,同时实现整体减重。

核心特点

- 可预测的能量吸收能力

- 高效的多轴载荷管理

- 无缝融入装配流程

相关解决方案

L&L Continuous Composite Systems™

CCS™ 提供高性价比、高强度的增强系统,助力提升碰撞性能、冲击耐久性和车辆轻量化水平。

核心特点

- 等截面

- 轻量化结构升级

- 高效管理冲击能量

- 提升耐用性和 NVH 控制效果

- 装配简便高效

相关解决方案

复合面板增强

复合面板增强件可提高无支撑面板区域的刚度,最大限度减少疲劳损耗,并提升 NVH 性能。该增强贴片可整合结构胶与玻璃布增强面料。

核心特点

- 支持使用更薄的面板材料

- 减少面板振动

- 抗长期疲劳

- 未固化状态下粘接性强

相关解决方案

密封工程解决方案

我们的发泡密封剂用于填充和密封结构腔体,防止水、空气、灰尘和烟雾侵入。这些材料在电泳涂装前应用,并在烘道中固化。

核心特点

- 密封复杂腔体

- 针对特定应用定制设计

- 轻量化材料

- 具备缝隙填补能力

相关解决方案

扭矩保持 - 隔离 - 密封解决方案

TRI-Seal® 采用发泡材料,内嵌刚性、抗挤压球体,可作为间隔物,同时保持夹紧载荷。适用于需要材料隔离或稳定载荷保持的接头密封。

核心特点

- 密封防水、防尘、防烟雾

- 最大限度减少扭矩衰减

- 防止电偶腐蚀

- 提供触感干燥型和自粘型产品

相关解决方案

声学

粘接

增强

密封

热管理

修复系列

Select a panel to see more information.

纤维基声学解决方案

用于 NVH 优化的结构发泡增强方案

PHASTER® 发泡增强材料填充腔体,以提高刚度,并助力降低噪声、振动与声振粗糙度(NVH)。

核心特点

- 提升车身刚度

- 密封车架,减少腔体传导噪声

- 常温固化

相关解决方案

弹性胶粘剂

L&L Seal弹性密封胶和粘合剂可用于粘接和密封多种基材,通常无需传统聚氨酯系统所需的预处理步骤。

关键特性

• 耐高温且持久耐用

• 无需底漆即可粘附于玻璃和涂漆表面

• 不含挥发性有机化合物、异氰酸酯及CMR

相关解决方案

常温固化结构胶

PHASTER® 结构胶与半结构胶提供发泡型与非发泡型两种类型,可满足各类粘接需求。

核心特点

- 对多种材质表面附着力强

- 发泡型产品可填充缝隙

- 非发泡型产品具备高剥离强度

- 无需涂覆底涂剂,也无需进行表面处理

相关解决方案

L&L Continuous Composite Systems™

CCS™ 是一款高强度、高性价比的增强解决方案,旨在提升碰撞防护性能与抗冲击性,同时助力实现产品轻量化设计。

横截面几何形状均匀

- 横截面几何形状均匀

- 增强结构强度的同时减轻产品重量

- 碰撞时可有效吸收并传导能量

- 提升振动控制效果与产品耐用性

- 便于集成到装配流程中

相关解决方案

常温固化发泡增强剂

PHASTER® 刚性发泡胶为双组分产品,可在常温下固化,能与多种基材粘接并发泡填充腔体,且规避了传统环氧树脂或聚氨酯系统存在的各类风险。

核心特点

• 适用于多种材质的粘接

• 发泡后可填充缝隙与腔体

• 无需底涂剂,且无需打磨或预处理 *

*请务必遵循安全数据表(SDS)与技术数据表(TDS)的指导规范

相关解决方案

常温固化可泵送密封胶

此类单组分弹性密封胶可防止水和烟尘侵入,能够有效防止基材发生腐蚀。

核心特点

• 无需涂覆底涂剂

• 相较于聚氨酯类产品,安全风险更低

• 在不同温度环境下均具备出色的耐用性

相关解决方案

扭矩保持 - 隔离 - 密封一体化解决方案

TRI-Seal® 粘性密封系统内嵌刚性球体,可有效抵抗压力,既能维持夹紧载荷,又能实现不同材质间的隔离。

核心特点

• 防止水、灰尘与烟雾侵入

• 长期使用可最大限度减少扭矩损失

• 杜绝电偶腐蚀

相关解决方案

隔热优化定制工程解决方案

我们的无纺布纤维基隔热产品提供平板裁切型与热成型两种类型,可根据不同隔热需求设计为单层或多层结构。

核心特点

- 薄型化性能优异:相较于棉屑材料,厚度减少 25%

- 助力轻量化设计:相较于棉屑材料,重量减轻 20%

相关解决方案

无纺布纤维基隔热材料

DECI-TEX® 产品线涵盖纤维基隔热与声学材料,在实现轻量化、薄型化的同时保证高性能,提供卷材与片材两种形态。

核心特点

• 轻量化设计

• 具备防潮、防火性能

• 可完全回收利用

相关解决方案

轻量化复合隔热罩

采用先进发泡技术打造高强度、轻量化板材,显著提升隔热性能与振动噪声控制(NVH)性能。

核心特点

- 一体成型的声学与隔热罩

- 相较于传统工艺,铺层速度更快,生产周期更短

- 无需核心胶粘剂,即可实现发泡与粘接一体成型

相关解决方案

PHASTER™ 内饰件修复产品

PHASTER™ 修复系列产品可快速、持久地修复内饰部件,帮助恢复产品原有的NVH性能与结构强度。

核心特点

• 发泡修复受损装饰区域

• 无需底涂剂,即可粘接多种材质表面

• 恢复密封性能与声学性能

• 便于在狭小空间操作

• 适配自动化设备与人工操作工具

相关解决方案

粘接

增强

密封

热管理

Select a panel to see more information.

弹性胶粘剂

这些材料用于电池系统内组件的粘接和密封,不含异氰酸酯。提供 UL 94 HB 级和 V-0 级产品。

核心特点

- 无需底涂

- 相比聚氨酯基材料,危险性更低

- 优异的耐用性和温度稳定性

相关解决方案

复合结构增强技术

CBS™ 可提升部件截面稳定性,实现载荷路径过渡,应对多向载荷,同时通过能量吸收提升碰撞防护性能,助力达成轻量化设计目标。

核心特点

• 能量吸收性能可精准预测

• 有效控制冲击能量

• 简化装配流程

相关解决方案

L&L Continuous Composite Systems™

CCS™ 是一款高性价比、超高强度的增强解决方案,可提升车辆翻滚防护性能、碰撞安全性与抗冲击性,同时推动产品轻量化。

核心特点

• 等截面设计

• 轻量化结构增强

• 有效控制冲击能量

• 提升振动控制效果与产品耐用性

• 易于融入生产制造流程

相关解决方案

常温固化发泡增强剂

PHASTER® 刚性发泡胶为双组分系统,可在室温下固化,能与多种基材牢固粘接并发泡填充缝隙,对腔体进行增强,且不存在传统环氧树脂或聚氨酯材料常见的安全隐患。

核心特点

• 对多种材质粘接强度高

• 发泡填充缝隙与腔体

• 无需底涂剂,且无需表面预处理或打磨 *

*请务必参考安全数据表(SDS)与技术数据表(TDS)的指导规范

相关解决方案

电池密封

弹性密封解决方案专为保护电池外壳而设计,可抵御湿气、灰尘与化学物质侵蚀,同时适应因温度变化导致的热胀冷缩。

核心特点

• 隔绝外界污染物

• 适配热胀冷缩需求

• 零挥发性有机化合物(VOC)配方

• 设计使用寿命长,耐用性强

相关解决方案

轻量化复合隔热罩

此类先进发泡材料可制成高强度、轻量化板材,有效控制电池系统温度,且生产过程中加工流程清洁高效。

核心特点

• 相较于传统工艺,生产周期与铺层时间更短

• 无需额外核心胶粘剂,即可同步实现发泡与粘接

相关解决方案

为何选择 L&L Products

点击细分板块,了解详情.

资源

要了解L&L Products如何推动汽车市场的发展,请探索我们的专业资源,了解我们的材料技术如何应用于汽车制造的各个领域。