L&L SEAL

L&L XiP® (eXtrude-in-Place™)

L&L Seal

Robotically Dispensed Sealants for Automated Processes.

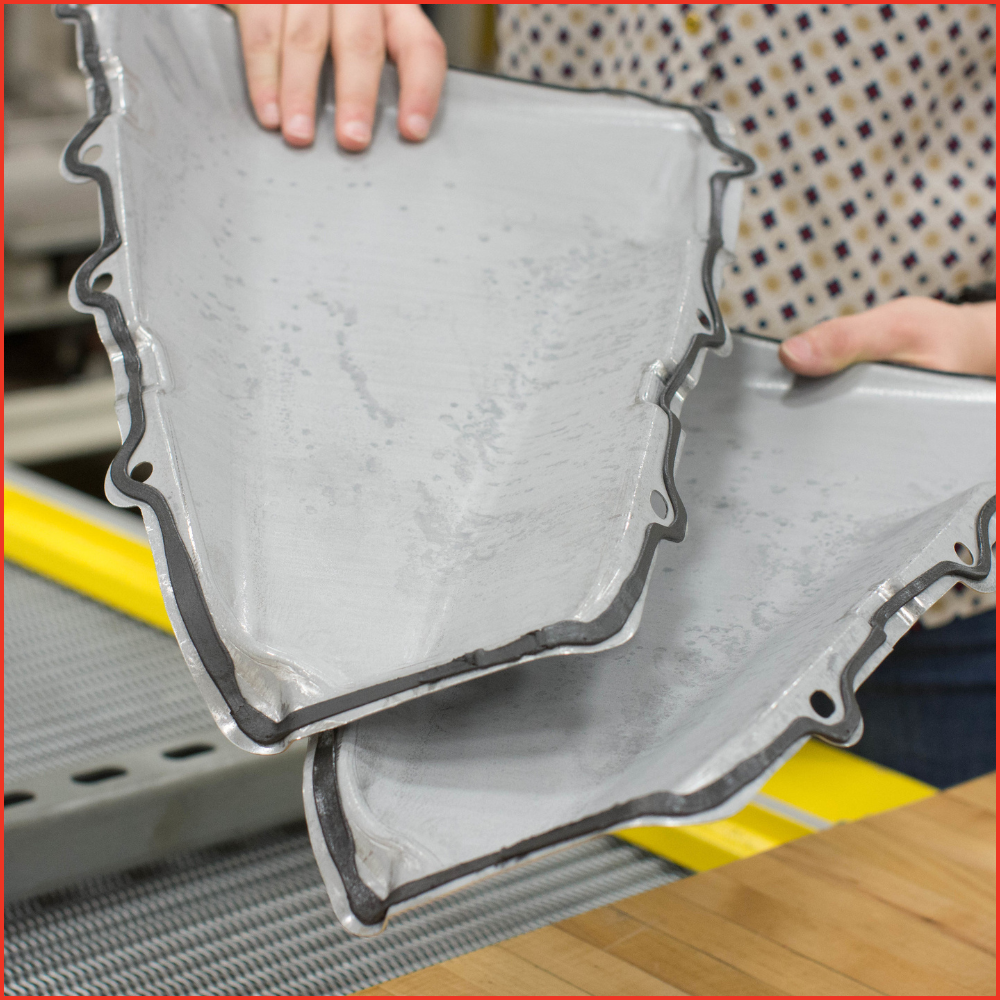

L&L XiP® compatible materials offer good wash-off resistance. Beyond that, they are formulated to be dry-to-the-touch immediately after being extruded onto the substrate, which leads to improved handling and enables the customer to stack or nest several parts, resulting in minimized packaging costs at a tier supplier or an offline cell.

The material can also be robotically applied inline for high repeatability, efficiency, and worker safety.

Why

L&L XiP®?

AUTOMATION

Flexibility to adjust where and when the material is applied, enabling versatile design capability.

DRY-TO-THE-TOUCH

The material is solid for easy handling and enables stacking of parts for minimized packaging costs and convenient transport.

LOGISTICS

The material used in L&L XiP® process is shipped in convenient pellet form to OEMs for inline application or to Tier 1 plant for production in an offline cell.

REDUCED WASTE

L&L XiP® eliminates waste from purging pumpable materials, offal from die-cut parts, and wash-off in the E-coat bath.

Product Attributes

- High level of repeatability for applications of varying complexity for acoustic and sealing performance

- Enables automated, precise application

- Enables delivery of parts with the sealant material already in place and eliminates messy application

- No odor or emissions

- Superior green-state adhesion

- Available forms include pellets and co-extruded rope

Application Areas

TRANSPORTATION

- Door beams

- Roof bows

- Front fender baffles

- Rear lamp

- Pillar closures

- Fuel fillers

Resources

Download our resources to find out how our L&L XiP™ (eXtrude-in-Place™) can be tailored to your needs.