L&L SealOffering robust sealing solutions for 50+ years

In the 1970s, we developed heat-activated polymeric sealing materials. Since then, we have worked consistently on optimizing our sealing technology by leveraged our polymer science and adhesion technology expertise and expanded our portfolio offerings.

Let’s get in touch!

Are you interested in our Seal Solutions? We look forward to a conversation!

ContactSeal

Solutions

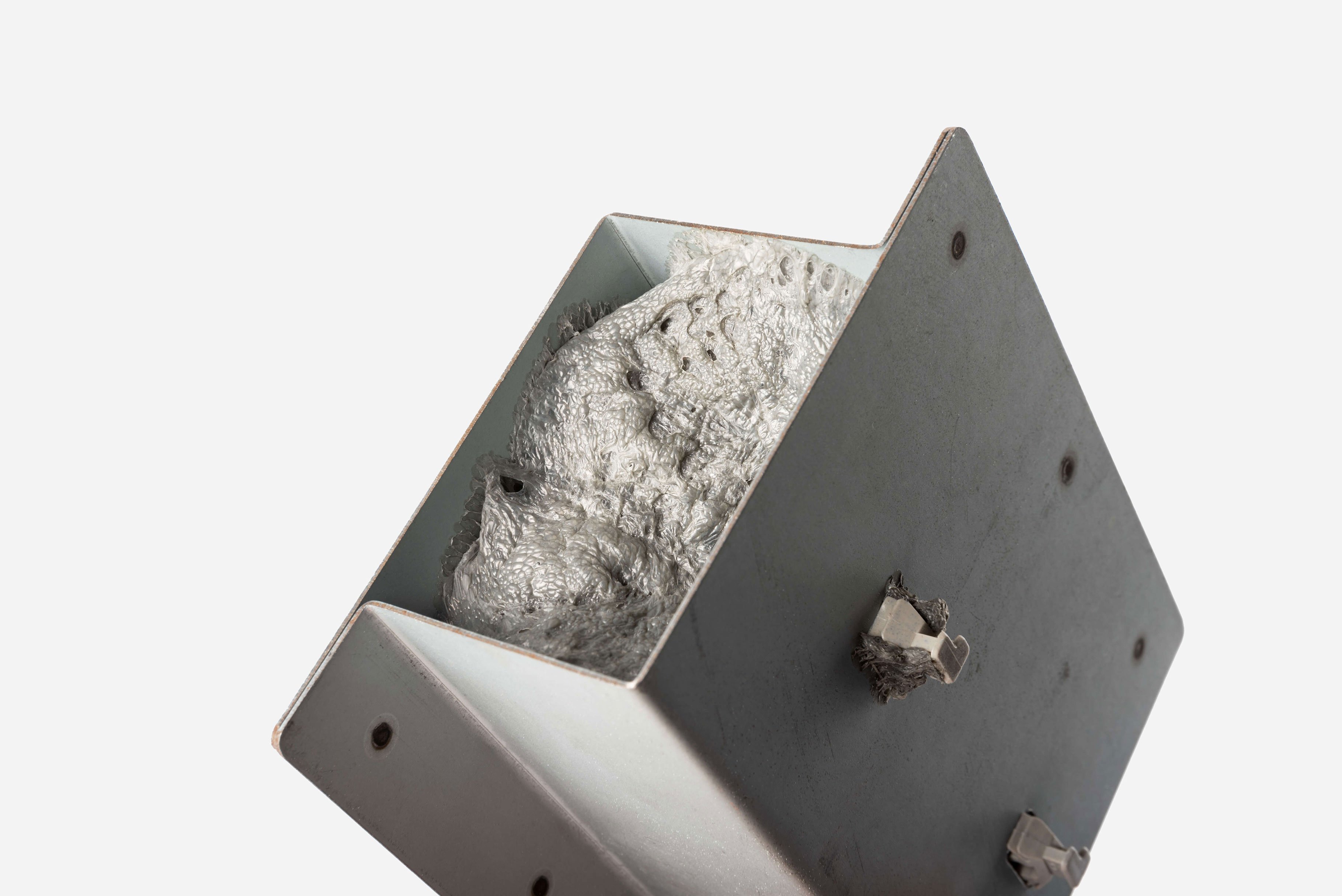

Our custom-formulated sealing materials are designed to completely fill and seal a cavity to prevent the intrusion of water, air, dust and fumes into the interior. By sealing even the most complex cavities, our solutions help to reduce metal body corrosion associated with water leaks and reduce noise, vibration, and harshness (NVH).

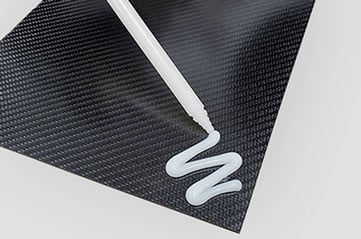

Ambient Curing Sealants

About

Key Attributes

Benefits

Applications

More

About

Key Attributes

Benefits

Applications

More

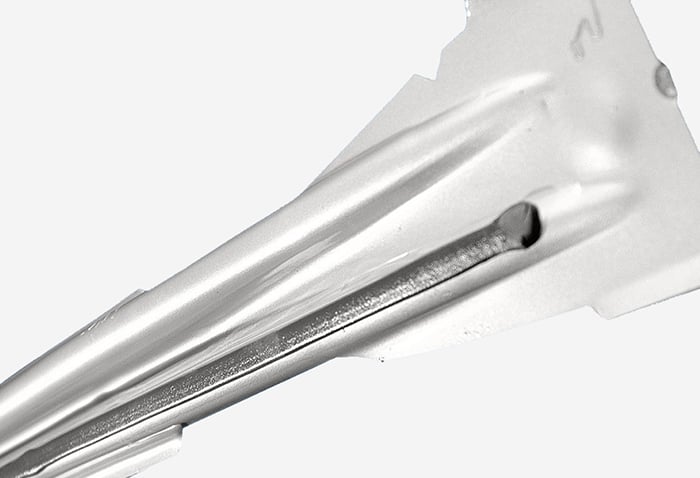

L&L TRI-Seal® (Torque Retention Isolation Sealing Solutions)

About

Key Attributes

Benefits

Applications

More

L&L XiP® (eXtrude-in-Place™) Technology