L&L BOND

L&L Bond

Fire, Smoke, and Toxicity (FST) Adhesives for Lightweight Assemblies.

L&L Bond Advanced Composite Adhesives introduce a series of lightweight FST-compliant adhesives that allow honeycomb cores to be bonded and reinforced in strategic areas. Well-suited to aerospace and rail interior applications, these adhesives are capable of multi-material bonding including metal, thermoplastics, and composites.

The materials are optimized for production efficiency which enable cost reduction and fast cycle times. L&L’s Advanced Composite Adhesives meet the latest FAA and EASA fire regulations for vertical burn, smoke density, and toxicity.

Why Advanced

Composite Adhesives?

HIGH STRENGTH

L&L Bond Advanced Composite Adhesives provide high strength mechanical bonds on bonds dissimilar substrates and gives strength to lightweight structures.

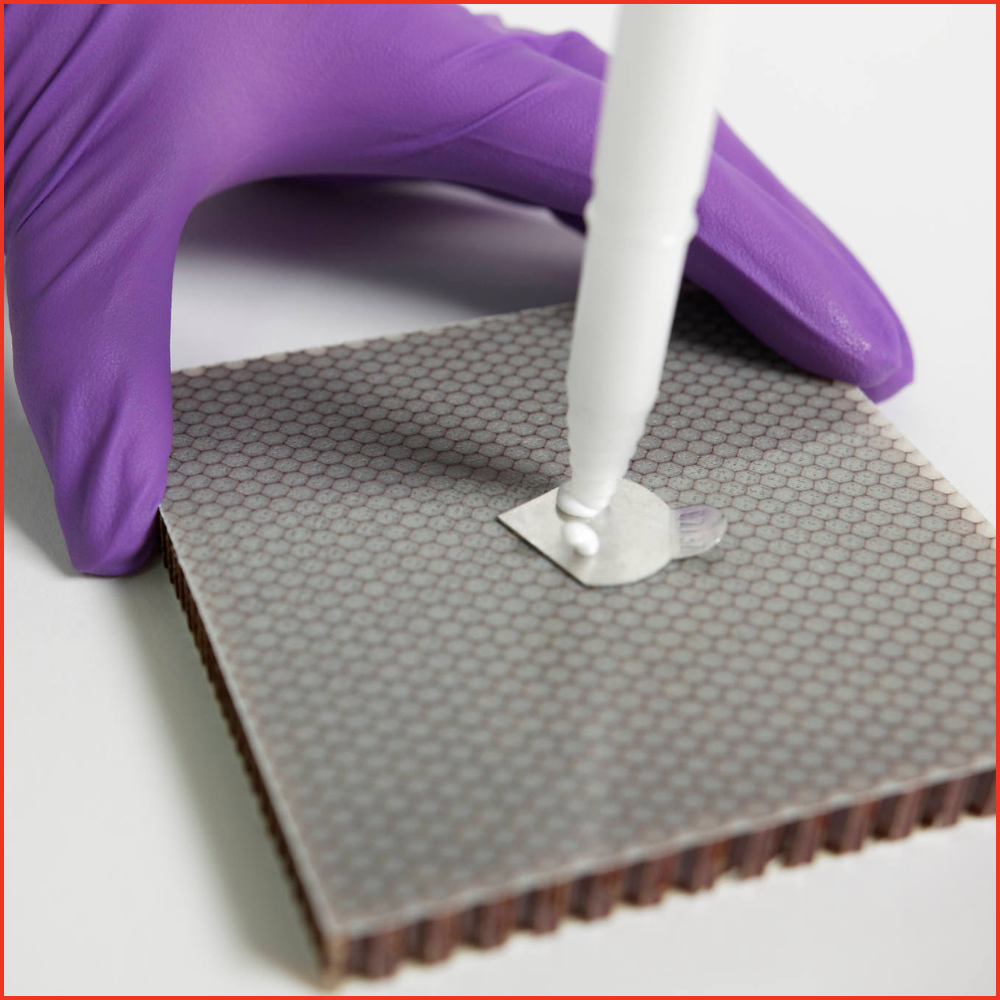

SAFE HANDLING

FST and REACH compliant, L&L’s Advanced Composite Adhesives provide operators with a clean, safe, and eco-friendly solution for composite bonding.

PROCESS

L&L Advanced Composite Adhesives cure at room temperature and requires less post-processing machining for improved process efficiency and overall cost reduction.

Product Attributes

- FST regulation compliant for simplified parts certification (FAR 25.853, ABD0031)

- Can be dispensed in a wide range of temperatures eliminating climate-controlled conditions

- Does not contain carcinogenic, mutagenic, or reproduction toxic (CMR) substances

- Accelerated cure possible with use of heat

- Smooth surface finish post-cure

Application Areas

APPLICATIONS IN VARIOUS MARKETS

- Insert bonding

- Bracket bonding

- Panel assembly

- Cut and fold operations

- Mortise-and-tenon assembly

- Aerospace

- Specialty Automotive

- Sporting goods

- Mass transit

- Marine

Resources

Download our resources to find out more on how L&L Bond Advanced Composite Adhesives can be tailored to your needs to provide superior performance and safe handling when bonding composite applications.