L&L SEAL

Heat-Activated Sealants

L&L Seal

Sealing Without Compromises.

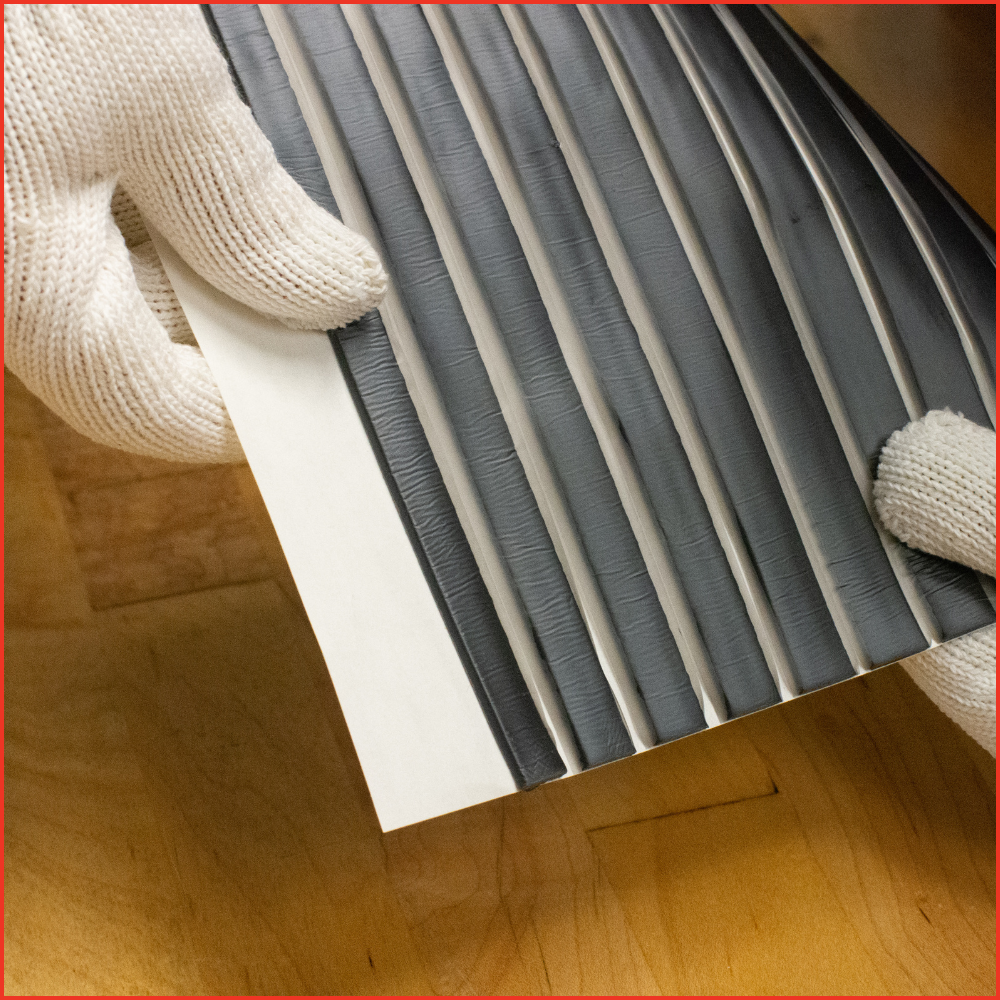

L&L Seal Heat-Activated Sealants are used for filling and sealing complex cavities to prevent the intrusion of water, air, dust, and fumes and to improve acoustic and noise, vibration, and harshness (NVH) performance.

L&L Seal Heat-Activated Sealant materials are applied prior to the E-coat process, foaming and curing in the E-coat oven to fill and seal cavities in vehicle frames. Offered in multiple forms, our lightweight Heat-Activated Sealants are engineered to meet specific customer needs such as activation under various time-temperature profiles, adhesion to different substrates, and resistance to certain environmental exposure conditions.

Additionally, sealing the body cavities at key locations in the vehicle results in improved overall acoustic performance and a quieter, more pleasant cabin environment. In order to completely fulfill requirements and needs, our technologies can be adapted to address specific frequencies and sound amplitudes.

Our acoustic sealant portfolio is formulated with varying levels of volumetric expansion, density and cell structure designed to minimize the amount of cavity-borne noise entering the cabin of a vehicle.

Why L&L

Heat-Activated Sealants?

PERFORMANCE

Superior green (uncured) adhesion of pressure-sensitive adhesives for temporary fixation prior to heat activation which creates a lightweight foaming solution for improved cabin experience.

DESIGN

Gap-jumping capabilities to bridge varying design gaps and complex cavity geometries.

PROCESS

Dry-to-touch sealants can be an efficient and economical alternative to messy pastes and liquids for reduced waste. Simple integration into existing bake cycles and manufacturing processes for operators or automation with no additional tools needed for application.

Product Attributes

-

L&L Heat Activated Sealants provides superior adhesion to oily vertical surfaces and remains in place during curing

-

Material resistance to certain environmental exposure conditions

-

Seals and protects body-in-white (BiW) from rust and corrosion

-

Variable volumetric expansion range from 0% – 2,000%

-

Can be configured for anti-flutter applications.

-

Solutions available for a range of bake processes

-

Low water absorption

-

Free of isocyanates (unlike PU-based injected foams)

-

Long shelf life compared to pumpable materials

-

Can either have an open or closed cell structure

Solutions

To achieve optimal sealing and acoustic performance, L&L Heat Activated Sealants are custom-engineered in multiple forms to best suit customer applications.

Application Areas

AUTO & COMMERCIAL VEHICLE

- Roof bows

- A, B, C, and D pillars

- Rockers

- Crossmembers

- Door beams

See our solutions and applications in action on the Automotive industry page and Commercial Vehicle industry page.

Resources

Download our resources to find out how our Heat-Activated Sealants can be tailored to your needs.