Automotive

Making Automobiles Lighter, Stronger and Quieter

At L&L Products, we help automotive manufacturers design vehicles that meet the highest standards of crash, comfort, and performance. Our advanced materials are engineered for lightweight construction, crash resistance, acoustic insulation, and multi-substrate bonding with each technology seamlessly integrating into modern production lines.

Whether you’re sealing cavities, reinforcing body structures, or optimizing NVH performance, our heat-activated and ambient-cured systems are built to meet the demands of today’s passenger cars, electric vehicles, and commercial fleets.

L&L Products is your partner for innovation

Click on segment to discover more.

Acoustic

Bond

Reinforce

Seal

Select a panel to see more information.

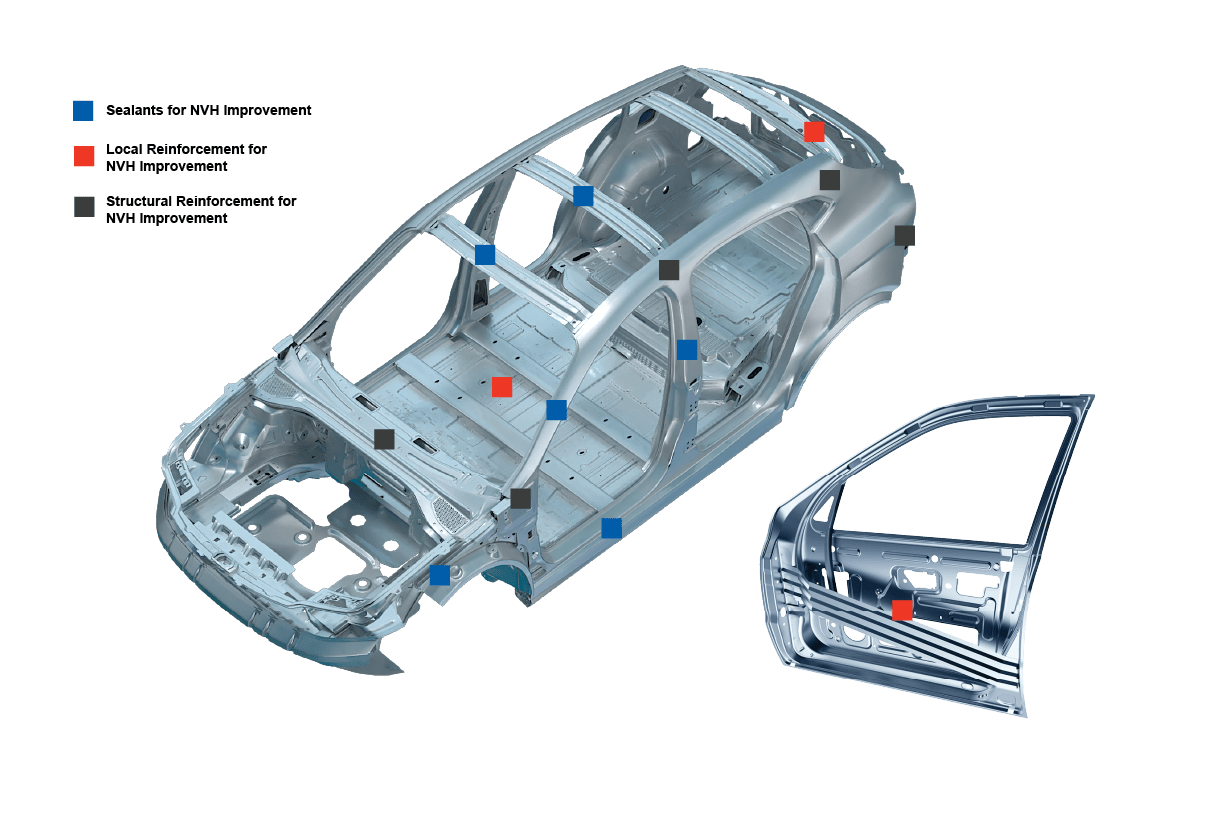

Sealants for NVH Improvement

Engineered solutions designed to seal and fill cavities within the frame, supporting NVH performance improvement while also protecting against water, dust, and fume intrusion.

Key Features

• Dry-to-touch parts for easy handling

• Seamless integration into manufacturing workflows

• Anti-flutter capabilities and acoustic improvement

• Available in multiple formats

Related Solutions

Local Reinforcement for NVH Improvement

Composite Panel Stiffeners increase panel rigidity, reduce fatigue over time, and enhance NVH in wide or unsupported areas. These solutions typically combine glass fabric reinforcement with a structural adhesive.

Key Features

• Panel vibration damping

• Long-term fatigue resistance

• Supports use of thinner gauge panels

• Excellent adhesion in green state

Related Solutions

Structural Reinforcement for NVH Improvement

CBS™ technology is integrated into regions of the frame to add stiffness and enhance NVH performance. These solutions combine engineered structural foams with custom-designed thermoplastic carriers.

Key Features

• Improves structural rigidity

• Heat-activated materials installed prior to E-coat

Related Solutions

Heat-Activated Solutions for Bonding

Applied before the E-coat process, these structural adhesive tapes activate during bake and may foam to bridge gaps where needed.

Key Features

• High ductility and strength

• Pressure-sensitive for pre-bake placement

• Enhances structural stiffness and durability

• Gap-jumping foam variants available

Related Solutions

Composite Structural Reinforcement Technology

CBS™ reinforcements offer sectional stability and multi-directional load path management to absorb energy, improve impact performance, and crashworthiness, as well as overall weight reduction.

Key Features

• Predictable energy absorption

• Effective multi-axis load management

• Seamless integration into the assembly process

Related Solutions

L&L Continuous Composite Systems™

CCS™ offers a cost-effective, high-strength reinforcement system that supports improved crash performance, impact durability, and vehicle lightweighting.

Key Features

• Consistent geometry across sections

• Lightweight structural upgrade

• Manages impact energy

• Increased durability and NVH control

• Simple, efficient assembly

Related Solutions

Composite Panel Reinforcement

Composite Panel Stiffeners increase stiffness in unsupported panel areas, minimize fatigue, and enhance NVH. These patches can incorporate a structural adhesive with glass fabric reinforcement.

Key Features

• Enables thinner panel materials

• Reduces vibration in panels

• Resists long-term fatigue

• Strong adhesion in green state

Related Solutions

Engineered Solutions for Sealing

Our foaming sealants are used to fill and seal structural cavities, preventing the entry of water, air, dust, and fumes. These materials are applied before E-coat and cure during oven processing.

Key Features

• Seals complex cavities

• Custom-designed for specific applications

• Lightweight material

• Capable of bridging gaps

Related Solutions

Torque Retention – Isolation – Sealing Solutions

TRI-Seal® uses a foaming material with embedded rigid, crush-resistant spheres that act as spacers while maintaining clamp load. Ideal for sealing joints that require material separation or consistent load retention.

Key Features

• Seals against water, dust, and fumes

• Minimizes torque fall-off

• Prevents galvanic corrosion

• Available in dry-to-touch and tacky formats

Related Solutions

Acoustic

Bond

Reinforce

Seal

Thermal

Repair

Select a panel to see more information.

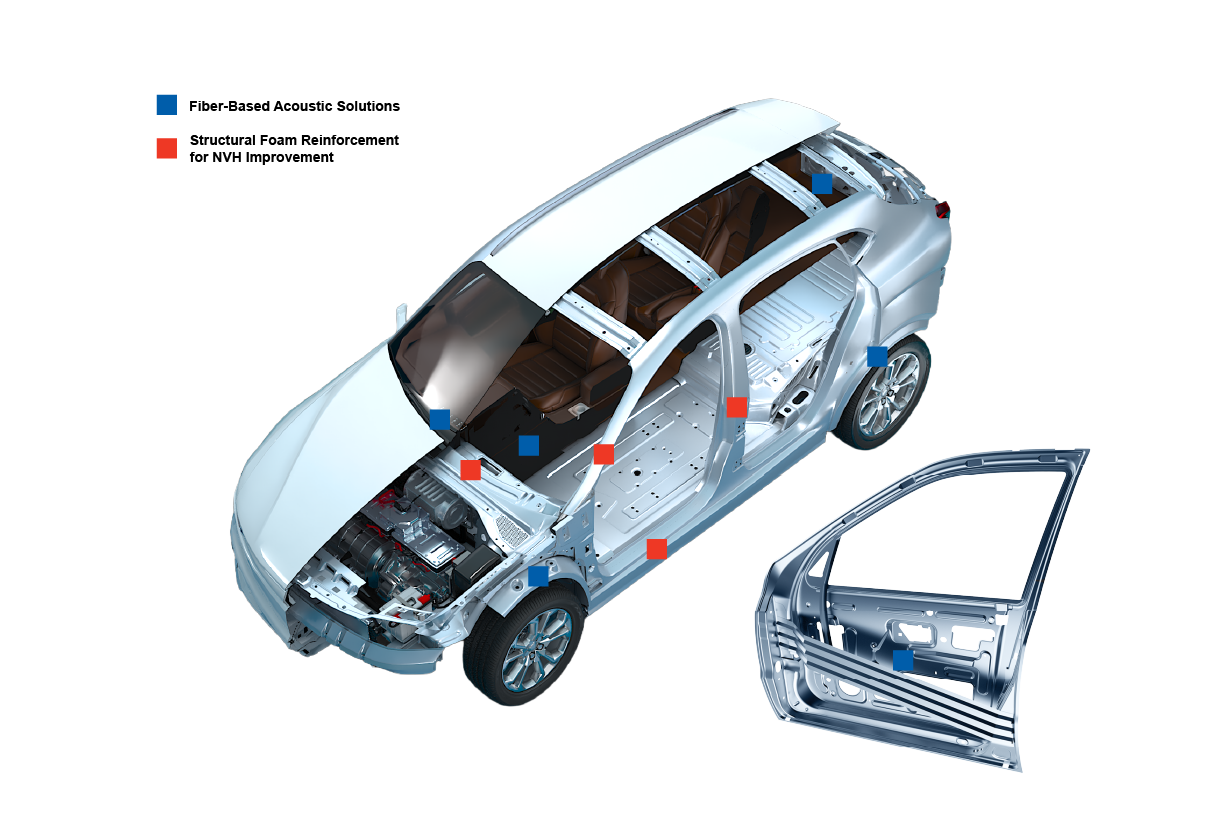

Fiber-Based Acoustic Solutions

Our advanced nonwoven fiber platforms are designed for effective acoustic absorption. These engineered solutions are highly customizable in terms of shape, layering, and format for a broad range of applications.

Key Features

• Lightweight and sound-absorbing

• Tailored fiber blends, thicknesses, and densities

• Supports thermoforming and die cutting

• Resistant to UV and flame exposure

Related Solutions

Structural Foam Reinforcement for NVH Improvement

PHASTER® foaming reinforcement materials fill cavities to improve stiffness and help reduce noise, vibration, and harshness (NVH).

Key Features

• Increases body stiffness

• Seals the frame to reduce cavity-borne noise

• Cures at ambient temperatures

Related Solutions

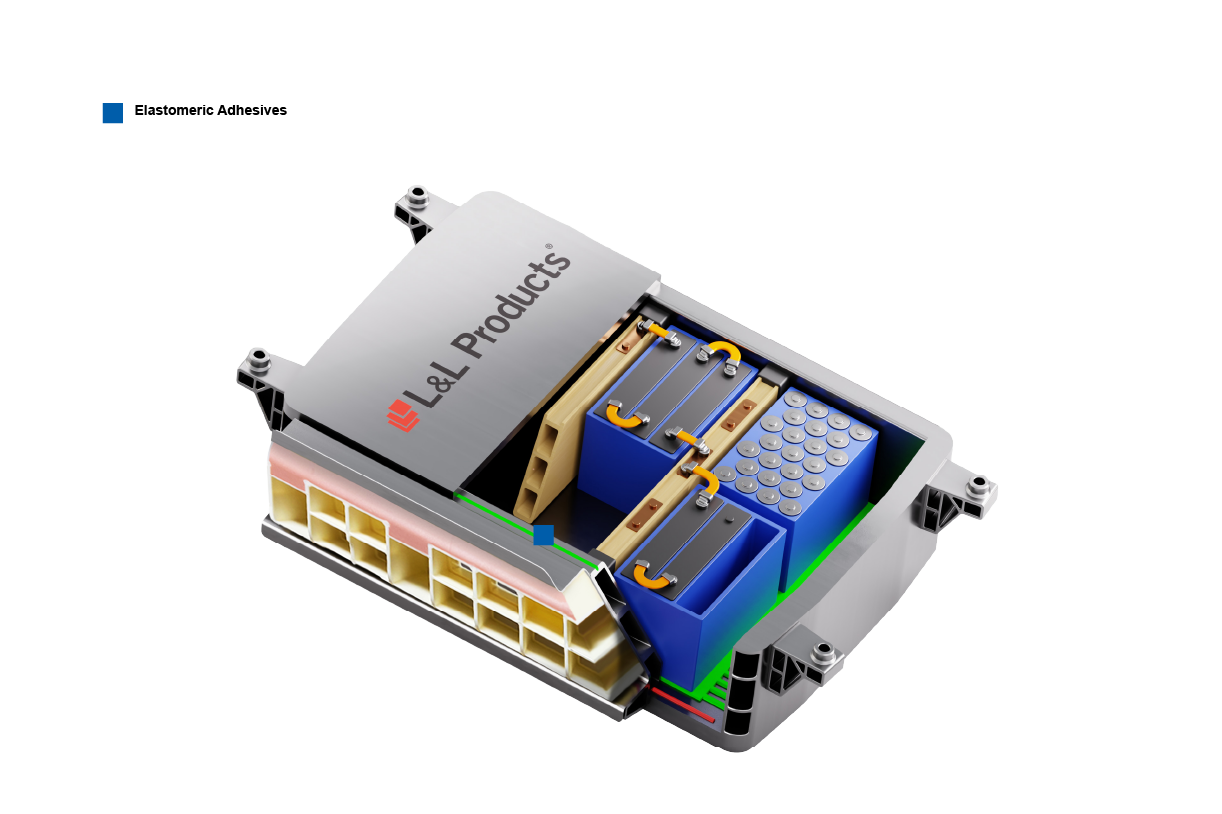

Elastomeric Adhesives

L&L Seal elastomeric sealants and adhesives are used to bond and seal many different substrates, often eliminating the need for the pretreatment steps typically required by traditional polyurethane systems.

Key Features

• Temperature-resistant and long-lasting

• Adheres to glass and painted surfaces without primer

• Free from VOCs, isocyanates, and CMR substances

Related Solutions

Ambient Cured Structural Adhesives

PHASTER® structural and semi-structural adhesives are available in foaming and nonfoaming versions to meet a variety of bonding needs.

Key Features

• Strong adhesion to a wide range of surfaces

• Foaming variants support gap-jumping

• Nonfoaming types provide high peel strength

• No primer or surface treatment required

Related Solutions

L&L Continuous Composite Systems™

CCS™ delivers a high-strength, cost-effective reinforcement solution designed to improve crash protection, impact resistance, and enable lightweight design.

Key Features

• Uniform cross-section geometry

• Enhances structure while reducing mass

• Manages energy during impact

• Increases vibration control and durability

• Simplified integration into assemblies

Related Solutions

Ambient Cure Foaming Reinforcements

PHASTER® Rigid Foaming Adhesives are two-component products that cure at ambient temperature, bonding to various substrates and expanding to fill cavities—without the risks of traditional epoxy or PU systems.

Key Features

• Adheres to a broad range of materials

• Foams to fill gaps and cavities

• Primerless adhesion with no abrasion or prep needed*

*Always follow SDS and TDS guidelines

Related Solutions

Ambient Cured Pumpable Sealants

These single-component elastomeric sealants are formulated to seal against water and fume entry, helping to prevent corrosion.

Key Features

• No primer required

• Reduced safety risks compared to PU products

• Excellent durability across temperature ranges

Related Solutions

Torque Retention – Isolation – Sealing Solutions

TRI-Seal® tacky sealant systems feature embedded rigid spheres that resist compression, supporting clamp loads and providing separation between different materials.

Key Features

• Protects against water, dust, and fume intrusion

• Minimizes torque loss over time

• Stops galvanic corrosion

Related Solutions

Engineered Solutions for Thermal Improvement

Our nonwoven fiber-based insulation solutions are manufactured as flat-cut or thermoformed parts and can be configured in single or multi-layer designs for various thermal needs.

Key Features

• Performs well in thinner layers: 25% less thickness vs cotton shoddy

• Supports lightweighting: 20% weight reduction vs cotton shoddy

Related Solutions

Nonwoven Fiber-Based Thermal Solutions

The DECI-TEX® product line includes fiber-based thermal and acoustic materials that offer high performance at reduced weight and thickness. Available in both roll and sheet formats.

Key Features

• Lightweight design

• Resistant to moisture and fire

• Fully recyclable

Related Solutions

Lightweight Composite Heat Shield

Our advanced foaming technology forms robust, lightweight panels that enhance thermal and NVH performance.

Key Features

- Net-shaped acoustic and thermal shields

- Faster layup and reduced cycle times compared to traditional methods

- Foams and adheres without needing core adhesives

Related Solutions

PHASTER™ Repair for Interior Components

PHASTER™ repair products offer quick and durable restoration of interior parts, helping regain lost NVH and structural performance.

Key Features

• Foaming repair for damaged trim zones

• Adheres to multiple surfaces without primer

• Restores sealing and acoustic properties

• Easy to use in tight spaces

• Compatible with robotic and manual tools

Solutions

Bond

Reinforce

Seal

Thermal

Select a panel to see more information.

Elastomeric Adhesives

These materials are used to bond and seal components within battery systems and contain no isocyanates. UL 94 HB and V-0 rated versions are available.

Key Features

• No primer needed

• Less hazardous than polyurethane-based materials

• Excellent durability and temperature stability

Related Solutions

Composite Structural Reinforcement Technology

CBS™ reinforcements provide enhanced section stability, enable load path transitions, manage multi-directional loads, and absorb energy to support crash protection, and lightweight design goals.

Key Features

• Highly predictable energy absorption

• Effective impact energy control

• Simplified assembly process

Related Solutions

L&L Continuous Composite Systems™

CCS™ is a cost-effective, ultra-high strength solution for reinforcement, supporting enhanced rollover performance, crash safety, impact protection, and lightweighting.

Key Features

• Uniform cross-sectional consistency

• Lightweight structural reinforcement

• Manages impact energy

• Improves vibration control and durability

• Easy to integrate into manufacturing

Related Solutions

Ambient Cure Foaming Reinforcements

PHASTER® rigid foaming adhesives are two-component systems that cure at room temperature. They adhere to a wide variety of substrates and expand to fill gaps, reinforcing cavities without the hazards typical of traditional epoxy or polyurethane materials.

Key Features

• Strong adhesion to diverse materials

• Foaming action fills gaps and cavities

• Primerless and no surface prep or abrasion needed*

*Always refer to SDS and TDS guidelines

Related Solutions

Battery Sealing

Elastomeric sealing solutions are designed to protect battery enclosures from moisture, dust, and chemical exposure while allowing for expansion due to temperature changes.

Key Features

• Protects against environmental contaminants

• Allows for thermal expansion

• VOC-free formulation

• Designed for long-term durability

Solutions

Lightweight Composite Heat Shield

These advanced foaming materials form strong, lightweight panels that help manage battery system temperatures, while offering clean, efficient processing during production.

Key Features

• Reduced cycle and layup time vs traditional methods

• Foams and bonds without separate core adhesives

Related Solutions

Why Choose L&L Products

Click on a segment to discover more.

Resources

To discover how L&L Products contributes to advancements in the automotive market, explore our dedicated resources and find out how our materials technologies can be adapted across automotive manufacturing.