L&L Products announces the launch of its proprietary InsituCore™ foaming materials for lightweight composite manufacturing. These new materials enable simplified production processes that result in a final lightweight net-shape part or preform with targeted density and strength.

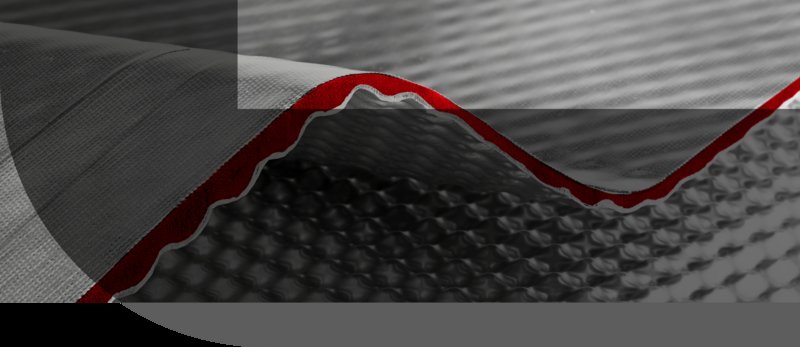

InsituCore™ Foaming Core Technology is a family of one-component, heat-activated foaming materials that generate internal pressure to create net shape, 3D parts that are both lightweight and strong in a simple, clean, and cost-effective process.

Placed in a heated tool, the InsituCoreTM material foams to fill the mold cavity and form net-shape parts without time-consuming machining processes or autoclave equipment. Compared to traditional manufacturing and machining methods such as liquid resin layups, split molding, and bladder molding, these materials enable faster cycle times, a reduction in waste material, and optimized production processes by eliminating secondary machining and assembly operations.

“The launch of InsituCore™ signals the arrival of more than just exciting new applications, said Jason Walker, Senior Application Engineer at L&L Products. “We’ve focused heavily on improving the entire composite manufacturing process from start to finish to be able to produce net-shape parts in a way that cuts down on waste and saves the customer time and money.”

Potential applications include sporting goods, aircraft tray tables, insulated panels, automotive OEM and aftermarket parts.

As part of the launch, L&L Products introduces its first two commercial products: InsituCore™ L-9008 is a one-component, heat-activated, thermosetting foam material that can be used to create foam core composites.

InsituCore™ L-9080 is a one-component, heat-activated, thermoplastic foam material that can be used to create foam core composites.

“InsituCore is an ideal alternative to traditional manufacturing and machining methods that have long gone unchanged,” said Blake Synnestvedt, Director of Business Development at L&L Products North America. “The composites industry has been due for an innovative solution that cuts down on waste and improves process times, and InsituCore is that product. As it becomes more widely used and field-tested, we look forward to helping customers leverage all the benefits of InsituCore™ to meet their unique needs. Along with other L&L Products solutions, InsituCore™ will be on display in September at the L&L Products booth at CAMX, the Composites and Advanced Materials Expo, with scheduled demonstrations at the Composites One Demo Zone.

For more information on InsituCore™, visit InsituCore.llproducts.com.

About L&L Products

L&L Products combines expertise in materials science, advanced engineering, and manufacturing process optimization for customers to develop unique solutions that deliver structural reinforcement, substrate bonding, static sealing, and acoustic improvement for automotive, aerospace, commercial vehicle, construction, and consumer products applications. For nearly 70 years, our skilled chemists, scientists, and engineers have collaborated with customers around the world to make products lighter, stronger, and quieter. Today, L&L has over 1200 employees worldwide, 10 manufacturing facilities, and locations in 15 countries. For more information, visit www.llproducts.com.

Links

http://www.llproducts.com/news/