L&L ThermalOptimized thermal insulation with tailor-made products

Most countries around the world are continuously seeking ways to limit the effect of transportation on the environment. For an internal combustion engine-powered vehicle to support these initiatives by reducing emissions and fuel consumption, there is a need to run the engine at significantly higher temperatures. L&L Products offers thermal management solutions to enable these higher temperature engines.

Let’s get in Touch!

Are you interested in our Thermal Management Solutions? We look forward to a conversation!

ContactEFS™ Thermal

Solutions

EFS™ Thermal solutions shield, protect, and help maintain engines to reduce emissions and fuel consumption. These solutions also help to reduce engine noise.

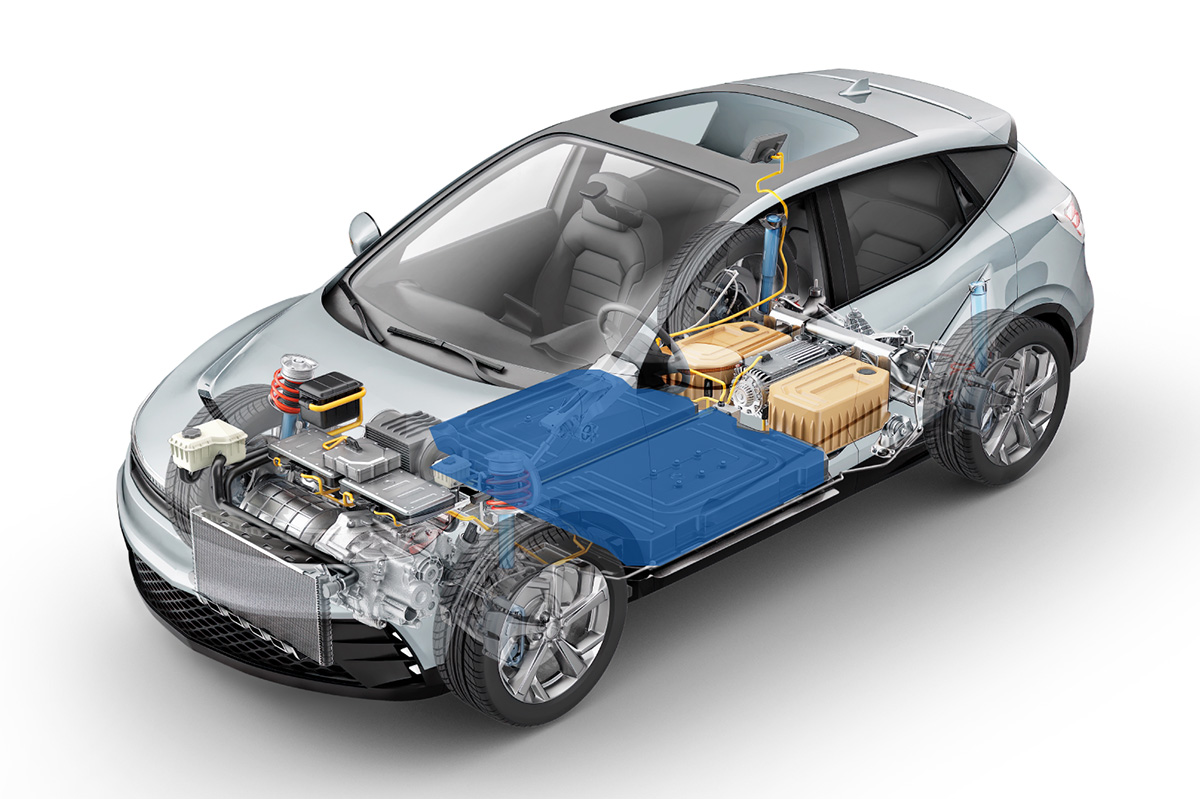

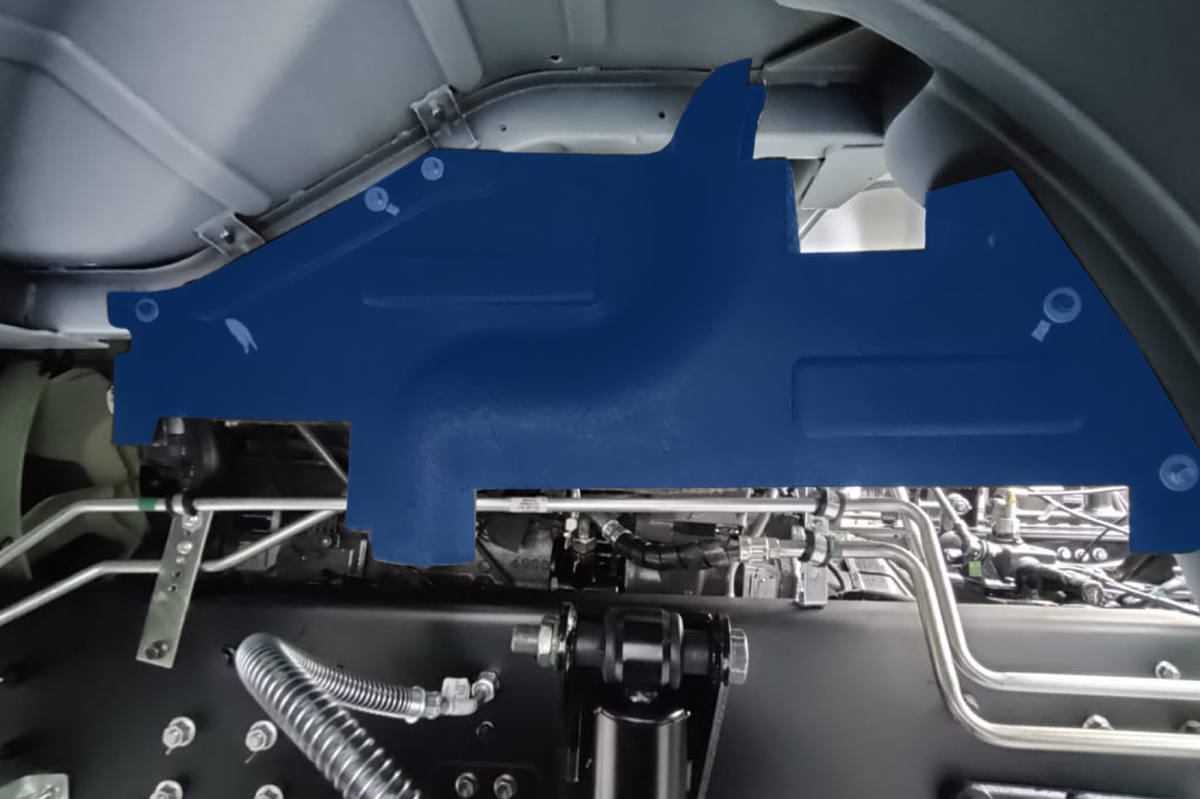

Battery Thermal Insulation

About

Key Attributes

BENEFITS

APPLICATIONS

MORE

Engine Bay Heat and Noise Shields

ABOUT

KEY ATTRIBUTES

BENEFITS

APPLICATIONS

MORE

Heat Shield

About

KEY ATTRIBUTES

BENEFITS

APPLICATIONS

MORE

Under-Hood and Under-Floor Thermal Insulation